Coin Production Process

1. Melting

Coinage materials are melted in an electric furnace, and ingots are produced by a continuous casting machine.

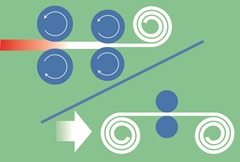

2. Hot Rolling & Cold Rolling

![]()

Moving Picture of 2. Hot Rolling & Cold Rolling

Ingots are heated in a soaking pit. While hot they are rolled out and made into coil shape. (Hot Rolling)

This is followed by rough and finish rolling to complete the rolled plates having the thickness of the coins to be produced. (Cold Rolling)

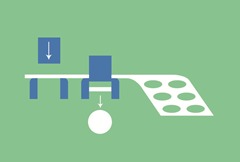

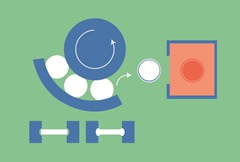

3. Blanking

Blank discs are punched from the finished plates. These are what we call "Engyo" (blanks).

4. Edging

To sharpen the images of coins, the peripheries of the blanks are edged. This is followed by annealing to soften the blanks.

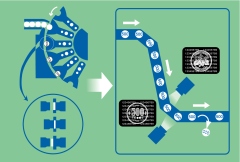

5. Coining & Inspecting

The obverse and reverse sides of the finished blanks are stamped with patterns, and edges are concurrently milled. Subsequently the pattern of each stamped coin is inspected, and imperfect products are taken out.

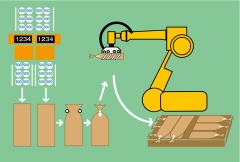

6. Counting & Bagging

![]()

Moving Picture of 6. Inspecting

Accepted coins are strictly counted, then bagged.