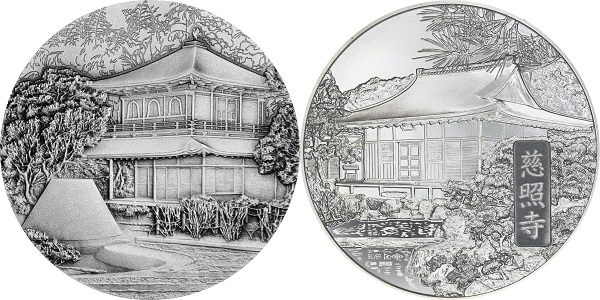

How National Treasure Medal “Jisho-ji (Ginkaku-ji)” is made? – from drawing designs to making data for the metal dies

1. Drawing designs

With reference to photos of Jisho-ji, designs of the medal are created.

2. Making a clay model

Based on the designs, a clay model is made. The model is shaped with a modeling tool made of Japanese boxwood that has very fine texture in order to add the subtle details. This step requires the skills of making a model with three-dimensional appearance and with depth within the height limitation.

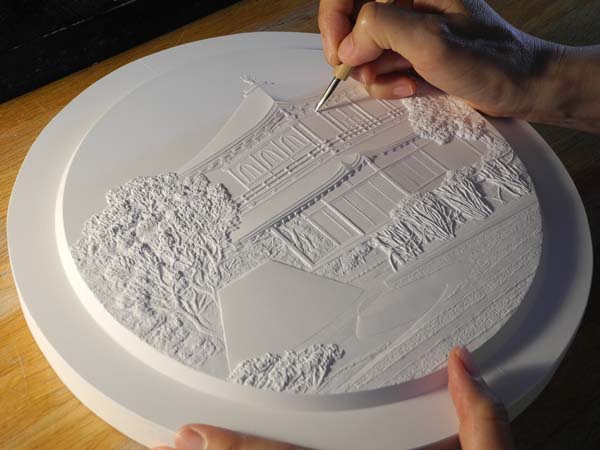

3. Making a plaster model

After pouring plaster into the clay model and taking it out, the tiny details are carved with an iron modelling tool and sandpaper while molding the concave and convexity sides in turns.

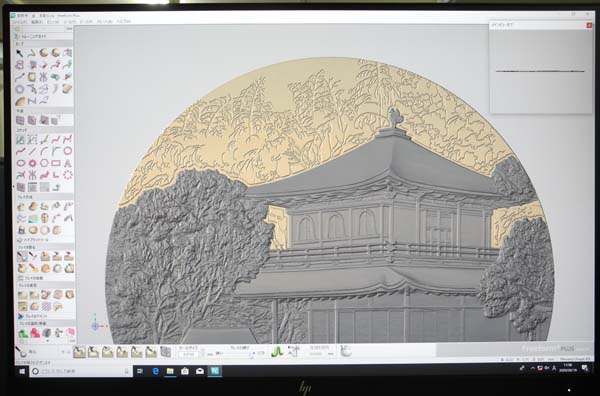

4. Combining the separate data

The concavity and convexity of the plaster model is scanned digitally and converted into the numerical data. And the data are combined with other data of the background of the medal design and kanji characters meaning “Jisho-ji”, and the data for dies of the medal is completed.

Special technique: Frosting finish processing technique

“Frosting finish processing technique” is a special processing technique of engraving a minutely irregular surface to diffuse reflection and offers a pearskin-like texture on the metal. It enables delicate gradation expression.

This technique is applied to the die of the Jisho-ji medal by laser processing. The surface of the pond on the medal is expressed by two tone colors realized by the technique.

*The photo shows the die of the medal (reverse), so the design is flipped horizontally compared with the final product.

*The enlarged photo of the above die showing the surface of the pond where “Frosting Finish Processing Technique” is applied.